| Mofuta oa tšepe oa tšepe | Tšepe ea hlobo: |

| Standard |

|

| Litlhaloso tsa tlhahiso | Letlapa la tšepe,Sheet, Coil,Flat bar,Round bar, Strip steel,terata,Mefuta eohle ea ho forging. |

| Mchining | Ho phethola Milling Ho sila Ho phunya lesoba le tebileng: bolelele ba limithara tse 9,8. |

| Sebaka sa mosebetsi | Round bar tšepe: 1mm ho 2000mm Tšepe ea sebopeho se sekwere: 10mm ho isa ho 1000mm tšepe Plate / lakane: 0.08mm ho 800mm Bophara: 10mm ho 1500mm Lenth: Re ka fana ka lente efe kapa efe ho latela tlhoko ea moreki. Ho theha: Shafts e nang le mapheo / liphaephe / li-tubes / slugs / donuts / cubes / libopeho tse ling Lithapo: OD: φ4-410 limilimithara, le botenya ba lebota ho tloha ho 1-35 mm. |

| Phekolo ea mocheso | Ho tloaeleha, ho futhumatsa, ho futhumatsa, ho tima, ho thatafatsa le ho futhumatsa, ho noa linoko, ho thatafatsa holim'a metsi, Carburizing |

AWS E10015-D2 MOSEBETSI OA K'hemik'hale LE MOSEBETSI OA MEHLENG:

| C ≤ | Si ≤ | Mn ≤ | P ≤ | S ≤ | Cr | Ni |

| 0.15 | 0.6 | 1.65-2.0 | 0.03 | 0.03 | ≤0.9 | |

| Mo | Al | Cu | Nb | Ti | V | Ce |

| 0.25-0.45 | ||||||

| N | Co | Pb | B | Tse ding |

MESEBETSI EA MEHLENG:

| Thepa | Maemo | ||

| T (°C) | Kalafo | ||

| Boima ba 'mele (×1000 kg/m3) | 7.7-8.03 | 25 |

|

| Karolelano ea Poisson | 0.27-0.30 | 25 |

|

| Elastic Modulus (GPA) | 190-210 | 25 |

|

| Tensile Strength (Mpa) | 1158 | 25 | oli e tingoa, e hloekisitsoe hantle, e halefile ho 425 ° C |

| Yield Strength (Mpa) | 1034 | ||

| Elongation (%) | 15 | ||

| Phokotso ea Sebaka (%) | 53 | ||

| Ho thatafala (HB) | 335 | 25 | oli e tingoa, e hloekisitsoe hantle, e halefile ho 425 ° C |

| Thepa | Maemo | ||

| T (°C) | Kalafo | ||

| Thermal Conductivity (W/mK) | 42.7 | 100 | |

| Mocheso o Khethehileng (J/kg-K) | 477 | 50-100 | |

LITABA TSA 'MELE:

| Bongata | Boleng | Yuniti |

| Katoloso ea mocheso | 16-17 | e-6/K |

| Thermal conductivity | 16-16 | W/mK |

| Mocheso o khethehileng | 500 - 500 | J/kg.K |

| Mocheso o qhibilihang | 1370 - 1400 | °C |

| Mocheso oa tšebeletso | 0-500 | °C |

| Botenya | 8000 - 8000 | kg/m3 |

| Ho hanyetsa | 0.7 - 0.7 | Ohm.mm2/m |

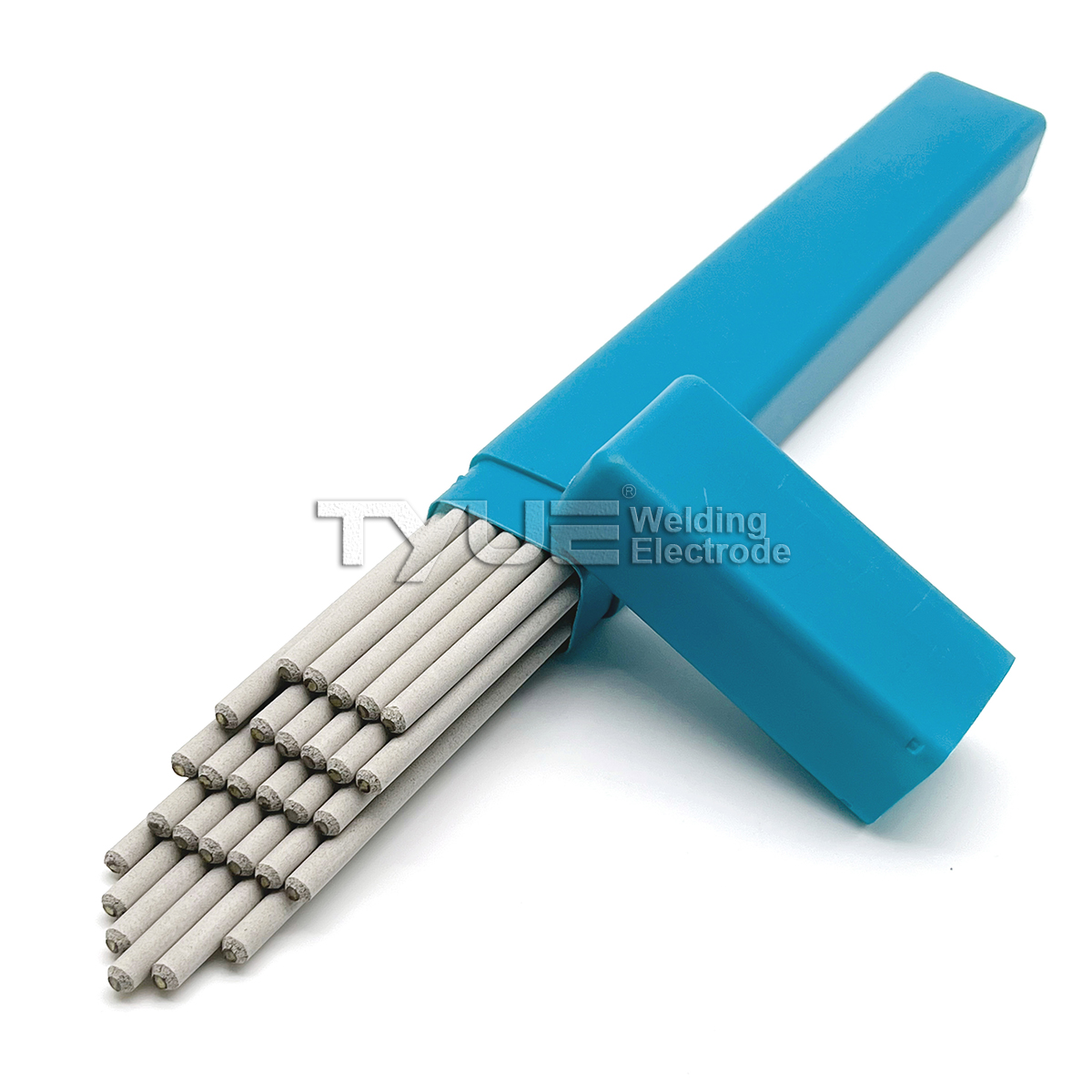

E7015-G Low Hydrogen Sodium Coating Welding Electrodes

TLHALOSO:

Ke molamu oa tšepe oa mocheso o tlase o nang le coating e tlase ea sodium hydrogen e nang le nickel.Welding ea boemo bo felletseng e ka etsoa ka khokahano ea dc reverse.Ho -80 ° C tšepe ea weld e ntse e na le matla a ts'usumetso e ntle.

SEBELISA:

Welded -80 ° C sebetsa 1.5Ni tšepe sebopeho.

TLHOKOMELISO EA METAL CHEMICAL COMPOSITED:

| C | Mn | Si | Ni | S | P | |

| Standard | ≤0.08 | ≤1.25 | ≤0.60 | ≥1.00 | ≤0.035 | ≤0.035 |

| Teko | 0.045 | 0.60 | 0.27 | 1.80 | 0.010 | 0.015 |

KETSAHALO EA TŠEBELETSO EA TŠEBELETSO EA TŠEBELETSO E HLAHANG:

| Tensile Strength Rm (MPa) | Yield Strength Rel (MPa) | Elongation A (%) | -80°C Boleng ba Kameho Akv (J) | |

| Standard | ≥490 | ≥390 | ≥22 | ≥27 |

| Teko | 530 | 445 | 30 | 100 |

TLHOKOMELISO CHELETE (DC+):

| Diameter (mm) | 3.2 | 4.0 | 5.0 | |

| Bolelele (mm) | 350 | 400 | 400 | |

| Hona joale (A) | 90-120 | 140-180 | 180-210 |

| E12015-G | Ho latela GB E8515-G E lumellana le AWS E12015-G |

Selelekela: E12015-G ke mofuta oa elektrode ea tšepe e nang le alloy e tlase e nang le mofuta o tlase oa hydrogen natrium.DCRP (Polarity ka ho toba Current Reversed).Ho tjheseletsa ka maemo ohle.

Lisebelisoa: E sebelisetsoa ho tjheseletsa meaho ea tšepe e nang le alloy e phahameng e nang le matla a ka bang 830MPa.

Motsoako oa lik'hemik'hale oa tšepe e behiloeng (%)

| Sebopeho sa Lik'hemik'hale | C | Mn | Si | S | P | Mo |

| Guarantee Boleng | ≤0.15 | ≥1.00 | 0.4~0.8 | ≤0.035 | ≤0.035 | 0.60 ~ 1.20 |

| Sephetho se Akaretsang | ≤0.10 | ~1,50 | ≤0.70 | ≤0.020 | ≤0.020 | ~0.90 |

Mechanical Properties of Deposited Metal

| Ntho ea Teko | Rm(MPa) | ReL kapaRp0.2(Mpa) | A(%) | KV2(J) |

| Guarantee Boleng | ≥830 | ≥740 | ≥12 | —(mocheso o tlwaelehileng) |

| Sephetho se Akaretsang | 860~950 | ≥750 | 12-20 | ≥27 |

Diffusable Hydrogen Content in Metal Deposited: ≤5.0ml/100g(Chromatography)

Tlhahlobo ea X-ray Radiographic: ⅠDegree

LITAELO:

1.Li-electrode li tlameha ho behoa tlas'a 350-400 ℃ bakeng sa hora pele ho tjheseletsa, li kenngoe ka har'a sekontiri sa ho kenya letsoho 'me li sebelise hang ha li hlokahala.

2.Matheba a tjheseletsang jwalo ka mafome a tlameha ho tloswa, mme weld e lokela ho futhumatswa pele ho 200℃.

3.Weld e ka halefisoa tlas'a 600-650 ℃ ka mor'a ho cheselletsa e le ho felisa khatello ea kelello ka hare.