| Mofuta oa sehlopha sa tšepe | Tšepe ea hlobo: |

| E tloaelehileng |

|

| Litlhaloso tsa tlhahiso | Poleiti ea tšepe, Sheet, Coil, Flat bar, Chitja bar, Strip steel, terata, Mefuta eohle ea forgings. |

| Ho chencha | Ho reteleha Ho sila Ho sila Ho phunya masoba a tebileng: bolelele bo boholo ke limithara tse 9.8. |

| Mefuta ea mosebetsi | Tšepe ea bare e chitja: 1mm ho isa ho 2000mm Tšepe e nang le sebopeho se sekwere: 10mm ho isa ho 1000mm Poleiti/leqephe la tšepe: 0.08mm ho isa ho 800mm Bophara: 10mm ho isa ho 1500mm Lenth: Re ka fana ka lenth efe kapa efe ho latela tlhoko ea moreki. Ho betla: Mehafo e nang le mahlakore/liphaephe/liphaephe/li-slug/li-donuts/li-cube/libopeho tse ling Liphaephe: OD: φ4-410 mm, ka botenya ba lebota bo tlohang ho 1-35 mm. |

| Kalafo ea mocheso | Ho lokisa, ho tjhesa, ho tjhesa, ho tima, ho thatafatsa le ho tjhesa, ho noka, ho thatafatsa bokahodimo, ho kenya khabone |

Sebopeho sa lik'hemik'hale sa AWS E10015-D2 le thepa ea mechini:

| C ≤ | Si ≤ | Mn ≤ | P ≤ | S ≤ | Cr | Ni |

| 0.15 | 0.6 | 1.65-2.0 | 0.03 | 0.03 | ≤0.9 | |

| Mo | Al | Cu | Nb | Ti | V | Ce |

| 0.25-0.45 | ||||||

| N | Co | Pb | B | Tse ling |

LITHEPA TSA MEKHANIKI:

| Matlo | Maemo | ||

| T (°C) | Kalafo | ||

| Botenya (×1000 kg/m3) | 7.7-8.03 | 25 |

|

| Karolelano ea Poisson | 0.27-0.30 | 25 |

|

| Modulus e Tenyetsehang (GPa) | 190-210 | 25 |

|

| Matla a ho Tenyetseha (Mpa) | 1158 | 25 | oli e timisitsoeng, e tšesaane, e besitsoeng mochesong oa 425°C |

| Matla a Tekanyo (Mpa) | 1034 | ||

| Ho lelefatsa (%) | 15 | ||

| Phokotso Sebakeng (%) | 53 | ||

| Boima (HB) | 335 | 25 | oli e timisitsoeng, e tšesaane, e besitsoeng mochesong oa 425°C |

| Matlo | Maemo | ||

| T (°C) | Kalafo | ||

| Ho Tsamaisa Mocheso (W/mK) | 42.7 | 100 | |

| Mocheso o Ikhethang (J/kg-K) | 477 | 50-100 | |

LITŠOANTŠISO TSA 'MELE:

| Bongata | Boleng | Yuniti |

| Katoloso ea mocheso | 16 - 17 | e-6/K |

| Ho khanna ha mocheso | 16 - 16 | W/mK |

| Mocheso o itseng | 500 - 500 | J/kg.K |

| Mocheso oa ho qhibiliha | 1370 - 1400 | °C |

| Mocheso oa tšebeletso | 0 - 500 | °C |

| Botenya | 8000 - 8000 | kg/m3 |

| Ho hanyetsa | 0.7 - 0.7 | Ohm.mm2/m |

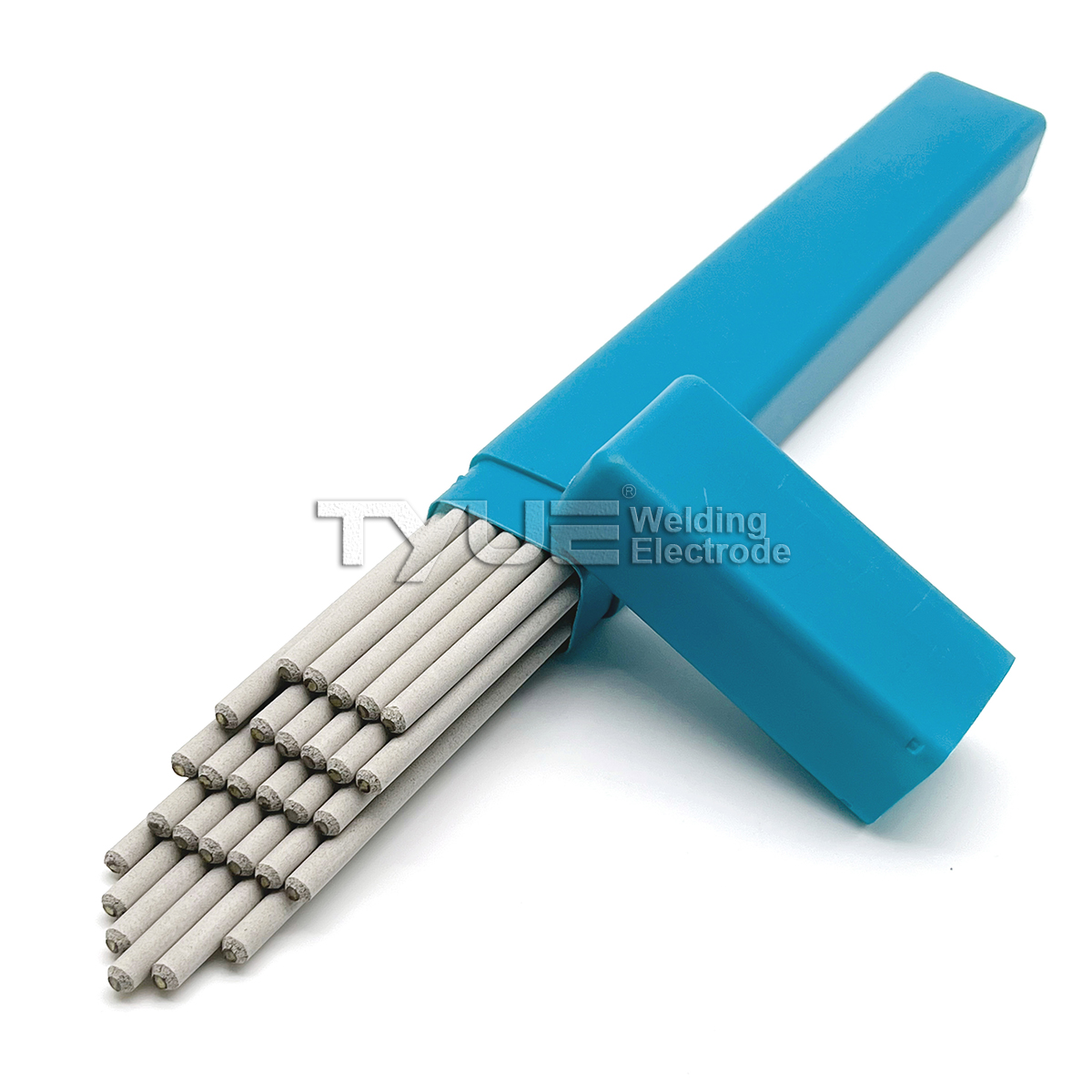

Li-electrode tsa ho tjheseletsa tsa ho koahela sodium e tlase ea E7015-G

TLHALOSO:

Ke thupa ea tšepe ea ho tjheseletsa e mocheso o tlase e nang le sekoahelo se tlase sa sodium hydrogen se nang le nickel. Ho tjheseletsa ka botlalo ho ka etsoa ka khokahano ea dc reverse. Tšepe ea ho tjheseletsa ka -80°C e ntse e na le matla a matle a ho tjheseletsa.

TŠEBELISO:

Sebopeho sa tšepe sa 1.5Ni se welded -80°C.

Sebopeho sa lik'hemik'hale tsa tšepe tse bolokiloeng:

| C | Mn | Si | Ni | S | P | |

| E tloaelehileng | ≤0.08 | ≤1.25 | ≤0.60 | ≥1.00 | ≤0.035 | ≤0.035 |

| Teko | 0.045 | 0.60 | 0.27 | 1.80 | 0.010 | 0.015 |

TS'EBELETSO EA MEKHENIKI EA TŠEPE E BEHILWENG:

| Matla a ho Tenyetseha Rm (MPa) | Matla a Tekanyo (MPa) | Tekanyo A (%) | Boleng ba Tšusumetso -80°C Akv (J) | |

| E tloaelehileng | ≥490 | ≥390 | ≥22 | ≥27 |

| Teko | 530 | 445 | 30 | 100 |

TLHOKOMELISO EA HONA JOALE (DC+):

| Bophara (mm) | 3.2 | 4.0 | 5.0 | |

| Bolelele (mm) | 350 | 400 | 400 | |

| Hona joale (A) | 90-120 | 140-180 | 180-210 |

| E12015-G | Ho ea ka GB E8515-G E tsamaellanang le AWS E12015-G |

Selelekela: E12015-G ke mofuta oa elektrode ea tšepe e matla e nang le motsoako o tlase e nang le seaparo sa mofuta oa natrium se nang le haeterojene e tlase. DCRP (Direct Current Reversed Polarity). Ho tjheseletsa ka hohle-hohle.

Ditshebediso: E sebediswa bakeng sa ho tjheseletsa meaho ya tshepe e nang le matla a tlase a nang le motswako o tlase e nang le matla a ho thaepa a ka bang 830MPa.

Sebopeho sa Lik'hemik'hale sa Tšepe e Behiloeng (%)

| Sebopeho sa Lik'hemik'hale | C | Mn | Si | S | P | Mo |

| Boleng ba Tiisetso | ≤0.15 | ≥1.00 | 0.4~0.8 | ≤0.035 | ≤0.035 | 0.60~1.20 |

| Sephetho se Akaretsang | ≤0.10 | ~1.50 | ≤0.70 | ≤0.020 | ≤0.020 | ~0.90 |

Matlotlo a Mekaniki a Tšepe e Lahliloeng

| Ntho ea Teko | Rm(MPa) | ReL kapaRp0.2(Mpa) | A(%) | KV2(J) |

| Boleng ba Tiisetso | ≥830 | ≥740 | ≥12 | —(mocheso o tloaelehileng) |

| Sephetho se Akaretsang | 860~950 | ≥750 | 12~20 | ≥27 |

Dikahare tsa haedrojene tse ka qhalanang ka hara tshepe e kentsweng: ≤5.0ml/100g (Chromatography)

Tlhahlobo ea X-ray ea X-ray: ⅠDegree

LITAELO:

1. Li-electrode li lokela ho besoa ka tlas'a 350-400℃ ka hora pele li tjheseletsa, li kenngoe ka har'a nkho ea ho thibela mocheso 'me li sebelisoe hang ha li hlokahala.

2. Matheba a ho weld a kang mafome a lokela ho tloswa, mme weld e lokela ho futhumatswa ho fihlela ho 200℃.

3. Weld e ka fokotsoa ka tlase ho 600-650℃ kamora ho tjheseletsa e le ho felisa khatello ea ka hare.