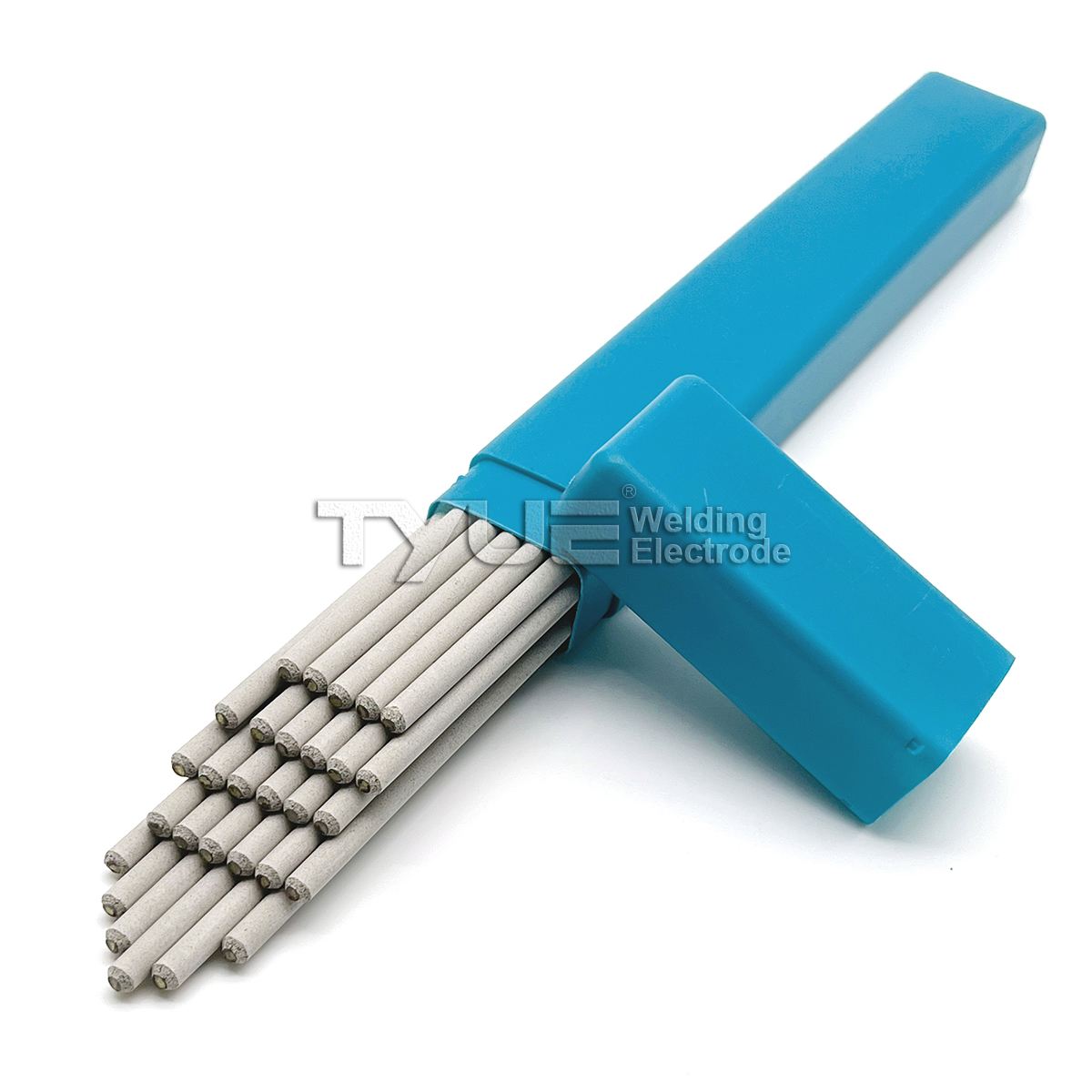

Alloy e tlaseHo cheselletsa tšepeElectrode

J607

GB/T E6015-D1

AWS E9015-D1

Tlhaloso: J607 ke electrode ea tšepe e nang le alloy e tlaase e nang le matla a tlaase a nang le sodium e tlaase ea hydrogen.Sebelisa DCEP (electrode e nepahetseng hona joale), 'me e ka chesetsoa maemong ohle.

Kopo: E sebelisetsoa ho tjheseletsa meaho ea tšepe e mahareng ea khabone le meaho ea tšepe e matla e tlase e nang le matla a tšoanang, joalo ka Q420, jj.

Sebopeho sa lik'hemik'hale tsa tšepe ea weld(%):

| C | Mn | Si | Mo | S | P |

| ≤0.12 | 1.25 ~ 1,75 | ≤0.60 | 0.25 ~ 0,45 | ≤0.035 | ≤0.035 |

Mechine ea tšepe ea weld:

| Ntho ea teko | Matla a tšepe Mpa | Ho hlahisa matla Mpa | Elongation % | Boleng ba tšusumetso (J) -30 ℃ |

| Guaranteed | ≥590 | ≥490 | ≥15 | ≥27 |

| Lekoa | 620 ~ 680 | ≥500 | Lilemo tse 20-28 | ≥27 |

Likahare tsa hydrogen tsa tšepe e kentsoeng: ≤4.0mL/100g (mokhoa oa glycerin)

Tlhahlobo ea X-ray: Ke ea sehlopheng

Nako e khothalelitsoeng:

| (mm) Bophara ba molamu | 2.0 | 2.5 | 3.2 | 4.0 | 5.0 | 5.8 |

| (A) Welding Current | Lilemo tse 60-80 | 70-90 | 90 ~ 120 | 140 ~ 180 | 170 ~ 210 | 210 ~ 260 |

Tlhokomeliso:

1. Electrode e tlameha ho behoa ka hora e le 1 ho 350 ℃ pele ho ts'ebetso ea welding;

2. Ho bohlokoa ho hloekisa mafome, sekala sa oli, metsi le litšila likarolong tsa ho cheseletsa pele ho tjheseletsa;

3. Sebelisa ts'ebetso e khuts'oane ea arc ha u cheselletsa.Tsela e moqotetsane ea ho tjheseletsa e nepahetse.