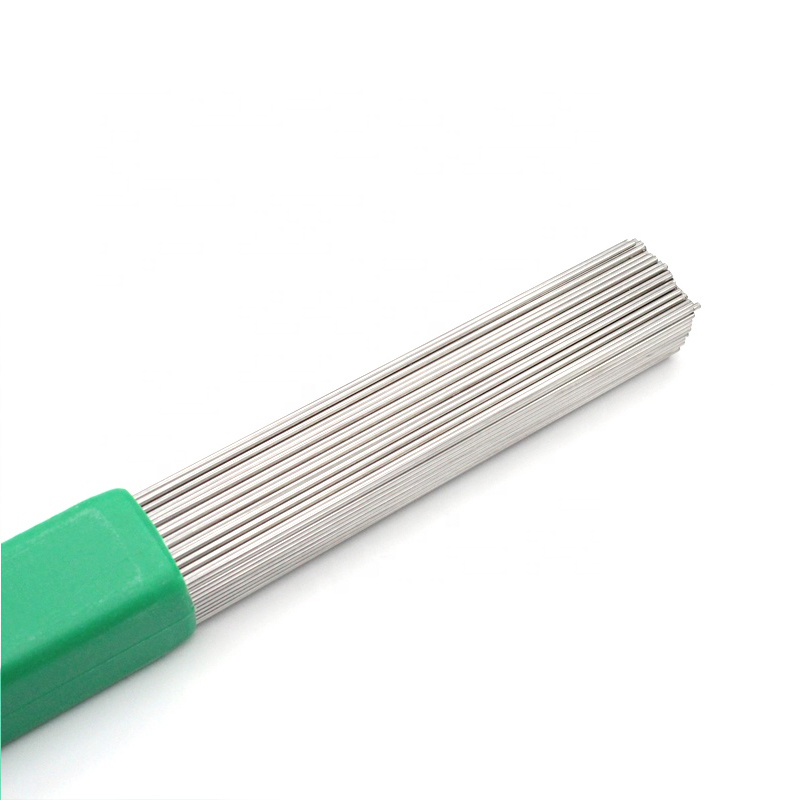

ER1100 A5.10, ALUMINUME LE ALLOY EA ALUMINUME Li-electrode le liropo

ER1100 e hanela haholo tlhaselo ea lik'hemik'hale le ho putlama ha tsona. Ke motsoako o bonolo haholo o ka etsoang habonolo 'me o sebelisoa haholo lihlahisoa tse tšesaane tsa gauge le tsa foil. E na le litšobotsi tse ntle tsa ho kolobisa 'me e boetse e sebelisoa e le motsoako oa ho tlatsa bakeng sa merero ea ho tjheseletsa. Tšobotsi e lakatsehang ea motsoako ke lipheletso tse khanyang tse fumanoang ka ho tlotsa.

Lisebelisoa tse Tloaelehileng: phapanyetsano ea mocheso; lisebelisoa tsa ho sebetsana le lijo; li-rivets; terata ea thae; ho etsa tšepe

| Sehlopha sa AWS: ER1100 | Setifikeiti: AWS A5.10/ A5.10M:1999 |

| Motsoako: ER1100 | AWS/ASME SFA A5.10 |

| Boemo ba ho tjheseletsa: F, V, OH, H | Hona jwale: DCEP-GMAW AC-GTAW |

Matlotlo a Tloaelehileng (joalokaha a tjhiditsoe)

| Ho tsamaisa motlakase: | 59% IACS (-12) |

| Matla a ho Tenyetseha, kpsi: | 13 |

| 'Mala: | Putsoa |

| Sebaka sa ho Qhibiliha | 1215⁰F | Ho tiea | 1090⁰F | Botenya | 0.098 lbs/cu Ka hare. |

K'hemistri e Tloaelehileng ea Lithapo ho latela AWS A5.10 (boleng bo le bong ke bo phahameng ka ho fetisisa)

| Si + Fe | Cu | Mn | Zn | Tse ling | Al | ||||||

| 0.95 | 0.05-0.20 | 0.05 | 0.10 | 0.15 | Metsotso e 99.0 | ||||||

| Liparamitha tse Tloaelehileng tsa ho Welding | |||||||||||

| Bophara | Tshebetso | Volt | Li-amplifier | KHASE | |||||||

| in | (mm) | ||||||||||

| .030 | (.8) | GMAW | 15-24 | 60-175 | Argon (cfh) | ||||||

| .035 | (.9) | GMAW | 15-27 | 70-185 | Argon (cfh) | ||||||

| 3/64” | (1.2) | GMAW | 20-29 | 125-260 | Argon (cfh) | ||||||

| 1/16” | (1.6) | GMAW | 24-30 | 170-300 | Argon (cfh) | ||||||

| 3/32” | (2.4) | GMAW | 26-31 | 275-400 | Argon (cfh) | ||||||

| Bophara | Tshebetso | Volt | Li-amplifier | KHASE | |||||||

| in | (mm) | ||||||||||

| 1/16” | (1.6) | GTAW | 15 | 60-80 | Argon (cfh) | ||||||

| 3/32” | (2.4) | GTAW | 15 | 125-160 | Argon (cfh) | ||||||

| 1/8” | (3.2) | GTAW | 15 | 190-220 | Argon (cfh) | ||||||

| 5/32” | (4.0) | GTAW | 15 | 200-300 | Argon (cfh) | ||||||

| 3/16” | (4.8) | GTAW | 15-20 | 330-380 | Argon (cfh) | ||||||

Wenzhou Tianyu Electronic Co., Ltd. e thehiloe ka selemo sa 2000. Re 'nile ra kopanela tlhahisong ea li-electrode tsa ho tjheseletsa, lithupa tsa ho tjheseletsa le lisebelisoa tse sebelisoang tsa ho tjheseletsa ka lilemo tse fetang 20.

Lihlahisoa tsa rona tse ka sehloohong li kenyelletsa li-electrode tsa tšepe e sa hloekang, li-electrode tsa tšepe ea khabone, li-electrode tsa ho tjheseletsa tse nang le alloy e tlase, li-electrode tsa ho tjheseletsa tse holim'a metsi, li-electrode tsa ho tjheseletsa tse nang le alloy ea nickel & cobalt, lithapo tsa ho tjheseletsa tse nang le alloy e bobebe le e nang le alloy e tlase, lithapo tsa ho tjheseletsa tse nang le alloy e sirelelitsoeng ke khase, lithapo tsa ho tjheseletsa tsa aluminium, ho tjheseletsa ka har'a arc e ka tlas'a metsi. lithapo, lithapo tsa ho tjheseletsa tse nang le alloy ea nickel & cobalt, lithapo tsa ho tjheseletsa tsa koporo, lithapo tsa ho tjheseletsa tsa TIG & MIG, li-electrode tsa tungsten, li-electrode tse sehang khabone, le lisebelisoa tse ling tsa ho tjheseletsa le tse sebelisoang.