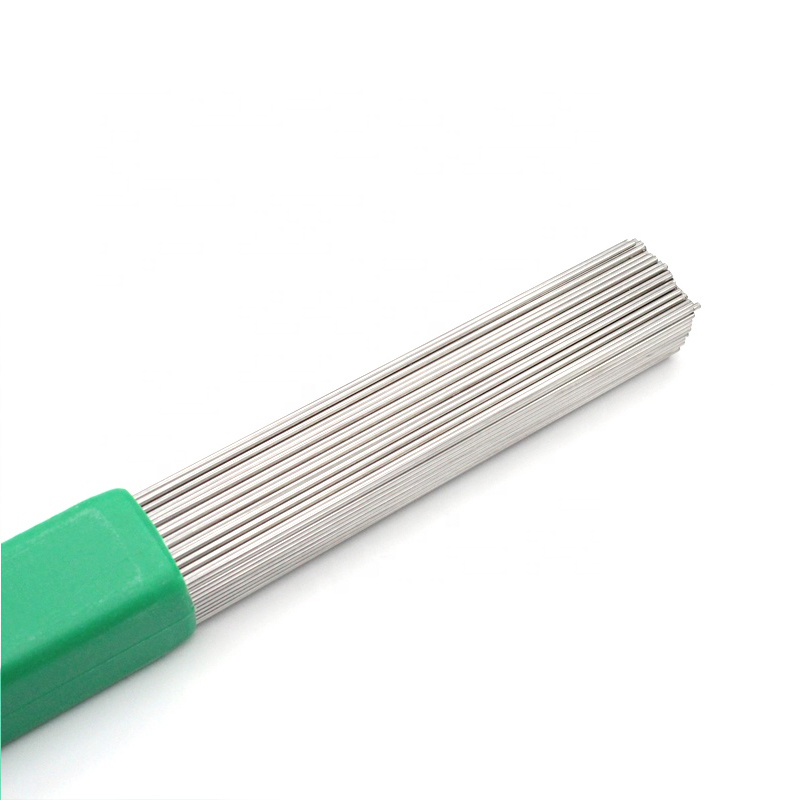

ER5183 e loketse MIG tjheseletsa alloy magnesium alloy hore ho hlokahala matla a phahameng a tensile mme haeba tšepe ea motheo e le 5083 kapa 5654 matla a tensile a ka ba holimo haholo.E sebelisoa haholo bakeng sa ho tjheseletsa aluminium magnesium alloy meaho ea likepe, sethala sa offshore, li-locomotives & likariki, likoloi tsa makoloi, lijana, likepe tsa cryogenic joalo-joalo.Tšepe ea eona ea weld e na le khanyetso e ntle ea ho bola ha brine.

Boemo ba Welding: F, HF, V

Mofuta oa Hona Joale: DCEP

TSEBISO:

Ho boloka sephutheloana sa terata se le maemong a matle pele ho tjheseletsa.

Likarolo tse peli tse lokelang ho chesetsoa ka weldment le terata li tlameha ho hloekisoa litšila tsa tšilafalo ea oli, ho roala oxide, mongobo joalo-joalo.

Ho fumana ponahalo e ntle ea weld ho hlokahala ho futhumatsa tšepe ea motheo ho 100 ℃-200 ℃ pele ho tjheseletsa haeba botenya ba eona e le 10mm kapa ho feta.

Ho molemo ho beha subplate tlas'a weld zone ho prop tšepe e qhibilihisitsoeng e le ho etsa bonnete ba ho kena ka ho feletseng tjheseletsa.

Ho ea ka boemo ba tjheseletsa le botenya ba tšepe motheo fapaneng thebe khase e lokela ho khethoa, tse kang 100% Ar, 75% Ar + 25% He, 50% Ar + 50% He, joalo-joalo.

Maemo a ho tjheseletsa a boletsoeng ka holimo bakeng sa ho buuoa feela 'me ho molemo ho etsa litlhoko tsa ts'ebetso ea welding ho ea ka morero pele o e kenya ka har'a welding e hlophisitsoeng.

ER5183 CHEMICAL COMPOSITION OF DEPOSITED METAL (%):

| SI | FE | CU | MN | MG | CR | ZN | TI | AI | BE | |

| Standard | ≤0.40 | ≤0.40 | ≤0.10 | 0.50-10 | 4.3-52 | 0.05-0.5 | ≤0.25 | ≤0.15 | Ho leka-lekanya | ≤0.0003 |

| E tloaelehileng | 0.08 | 0.12 | 0.006 | 0.65 | 4.75 | 0.130 | 0.005 | 0.080 | Ho leka-lekanya | 0.0001 |

LITABA TSA MACHHANICAL OF DEPOSITED METAL (AW):

| TENSILE STRENGTH RM (MPA) | YIELD STRENGTH REL (MPA) | ELONGATION A4 (%) | |

| E tloaelehileng | 280 | 150 | 18 |

Boholo le Tse khothalelitsoeng Hajoale bakeng sa MIG (DC+):

| WELDING WIRE DIAMETER (MM) | 1.2 | 1.6 | 2.0 |

| Welding Current (A) | 180-300 | 200-400 | 240-450 |

| Matla a ho Welding (V) | 18-28 | 20-20 | 22-34 |

BOKOLO LE BO KHOTHATSANG HO SEBELISA TIG (DC¯):

| WELDING WIRE DIAMETER (MM) | 1.6-2,5 | 2.5-4.0 | 4.0-5.0 |

| Welding Current (A) | 150-250 | 200-320 | 220-400 |

Wenzhou Tianyu Electronic Co., Ltd. e thehiloe ka selemo sa 2000. Re qetile lilemo tse fetang 20 re etsa li-electrode tsa welding, lithupa le lisebelisoa tsa ho cheselletsa.

Lihlahisoa tsa rona tse ka sehloohong li kenyelletsa li-electrode tsa tšepe tse sa hloekang, li-electrode tsa tšepe tsa carbon, li-electrode tse tlase tsa welding, li-electrode tsa welding, nickel & cobalt alloy welding wires, tšepe e bonolo le lithapo tse tlase tsa alloy, lithapo tsa tšepe tse se nang tšepe, likhoele tse sirelelitsoeng ka khase, lithapo tsa aluminium tse cheselletsang, li-arc tse kentsoeng ka metsing.lithapo, lithapo tsa nickel & cobalt alloy welding, lithapo tsa tšepe tsa koporo, lithapo tsa welding tsa TIG & MIG, li-electrode tsa tungsten, li-electrode tsa carbon gouging, le lisebelisoa tse ling tsa welding & consumables.