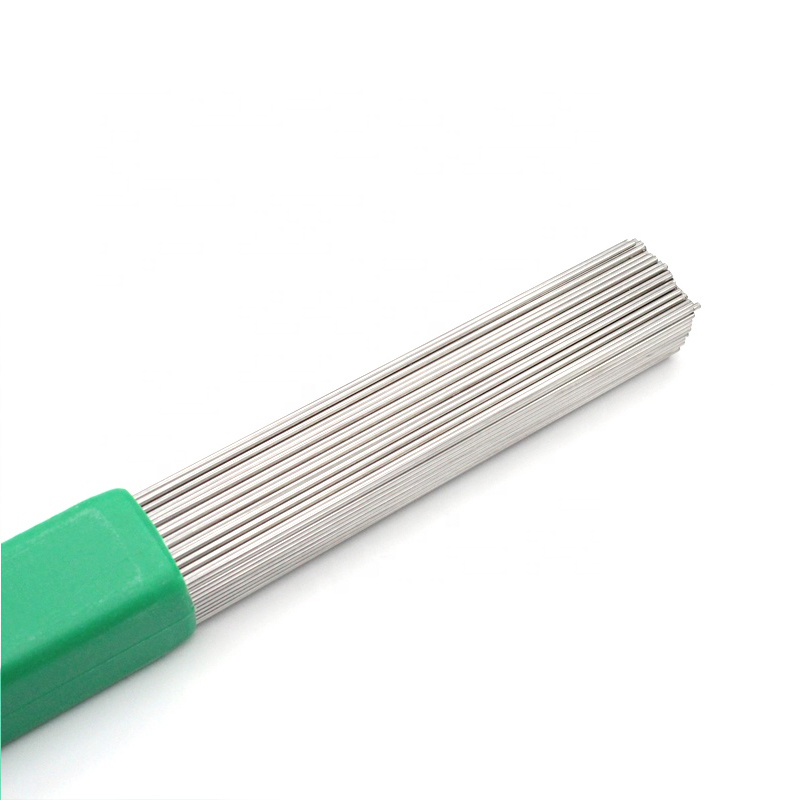

ER5183 e loketse ho tjheseletsa MIG motsoako wa aluminium magnesium moo matla a ho tjheseletsa a phahameng a hlokahalang mme haeba tshepe ya motheo e le 5083 kapa 5654 matla a ho tjheseletsa a ka ba a hodimo haholo. E sebediswa haholo bakeng sa ho tjheseletsa dibopeho tsa motsoako wa aluminium magnesium tsa dikepe, dipolatefomo tsa lewatle, diterene le dikariki, dikoloi, dikontenara, dikepe tse nang le cryogenic jj. Tshepe ya yona e tjheseletsang e na le kganyetso e ntle kgahlanong le mafome a metsi a lewatle.

Boemo ba ho tjheseletsa: F, HF, V

Mofuta oa Hona Joale: DCEP

TSEBISO:

Ho boloka sephutheloana sa terata se le boemong bo botle pele o tjheseletsa.

Libaka tse tla kopanngoa ka weldment le terata li lokela ho hloekisoa litšila tse bakoang ke tšilafalo ea oli, sekoahelo sa oxide, mongobo le tse ling.

Ho fumana ponahalo e ntle ea weld, ho hlokahala ho futhumatsa tšepe ea motheo ho fihlela ho 100℃-200℃ pele u e tjheseletsa haeba botenya ba eona e le 10mm kapa ho feta.

Ho molemo ho beha poleiti e nyenyane tlasa sebaka sa ho tjheseletsa ho tshehetsa tshepe e qhibilihisitsweng e le ho netefatsa hore ho tjheseletsa ho kenelle ka botlalo.

Ho ya ka boemo ba ho tjheseletsa le botenya ba tshepe ya motheo, kgase e fapaneng ya thebe e lokela ho kgethwa, jwalo ka 100%Ar, 75%Ar+25%He, 50%Ar+50%He, jj.

Maemo a ho tjheseletsa a boletsweng ka hodimo bakeng sa tshupiso feela mme ho molemo ho etsa setifikeiti sa tsamaiso ya ho tjheseletsa ho ya ka projeke pele o e kenya ho tjheseletsa ka semmuso.

ER5183 MOKHATLO OA K'HEMIK'HEMA OA TŠEPE E BEHILWENG (%):

| SI | FE | CU | MN | MG | CR | ZN | TI | AI | BE | |

| E tloaelehileng | ≤0.40 | ≤0.40 | ≤0.10 | 0.50-10 | 4.3-52 | 0.05-0.5 | ≤0.25 | ≤0.15 | Tekanyo | ≤0.0003 |

| E tloaelehileng | 0.08 | 0.12 | 0.006 | 0.65 | 4.75 | 0.130 | 0.005 | 0.080 | Tekanyo | 0.0001 |

LITHEPA TSA TŠEPE E BEHILWENG KA MEKHANIKI (AW):

| RM EA MATLA A HO THAMOA (MPA) | MATLA A HLAHISANG (MPA) | KELELLO A4 (%) | |

| E tloaelehileng | 280 | 150 | 18 |

Boholo le Khoeli e Khothaletsoang bakeng sa MIG (DC+):

| BORARO BA TERE EA HO WELDING (MM) | 1.2 | 1.6 | 2.0 |

| Ho tjheseletsa Hona Joale (A) | 180-300 | 200-400 | 240-450 |

| Motlakase oa ho Tjheseletsa (V) | 18-28 | 20-20 | 22-34 |

BOHOLO & KHOTSO E KHOTHALETSOANG BAKENG SA TIG (DC¯):

| BORARO BA TERE EA HO WELDING (MM) | 1.6-2.5 | 2.5-4.0 | 4.0-5.0 |

| Ho tjheseletsa Hona Joale (A) | 150-250 | 200-320 | 220-400 |

Wenzhou Tianyu Electronic Co., Ltd. e thehiloe ka selemo sa 2000. Re 'nile ra kopanela tlhahisong ea li-electrode tsa ho tjheseletsa, lithupa tsa ho tjheseletsa le lisebelisoa tse sebelisoang tsa ho tjheseletsa ka lilemo tse fetang 20.

Lihlahisoa tsa rona tse ka sehloohong li kenyelletsa li-electrode tsa tšepe e sa hloekang, li-electrode tsa tšepe ea khabone, li-electrode tsa ho tjheseletsa tse nang le alloy e tlase, li-electrode tsa ho tjheseletsa tse holim'a metsi, li-electrode tsa ho tjheseletsa tse nang le alloy ea nickel & cobalt, lithapo tsa ho tjheseletsa tse nang le alloy e bobebe le e nang le alloy e tlase, lithapo tsa ho tjheseletsa tse nang le alloy e sirelelitsoeng ke khase, lithapo tsa ho tjheseletsa tsa aluminium, ho tjheseletsa ka har'a arc e ka tlas'a metsi. lithapo, lithapo tsa ho tjheseletsa tse nang le alloy ea nickel & cobalt, lithapo tsa ho tjheseletsa tsa koporo, lithapo tsa ho tjheseletsa tsa TIG & MIG, li-electrode tsa tungsten, li-electrode tse sehang khabone, le lisebelisoa tse ling tsa ho tjheseletsa le tse sebelisoang.