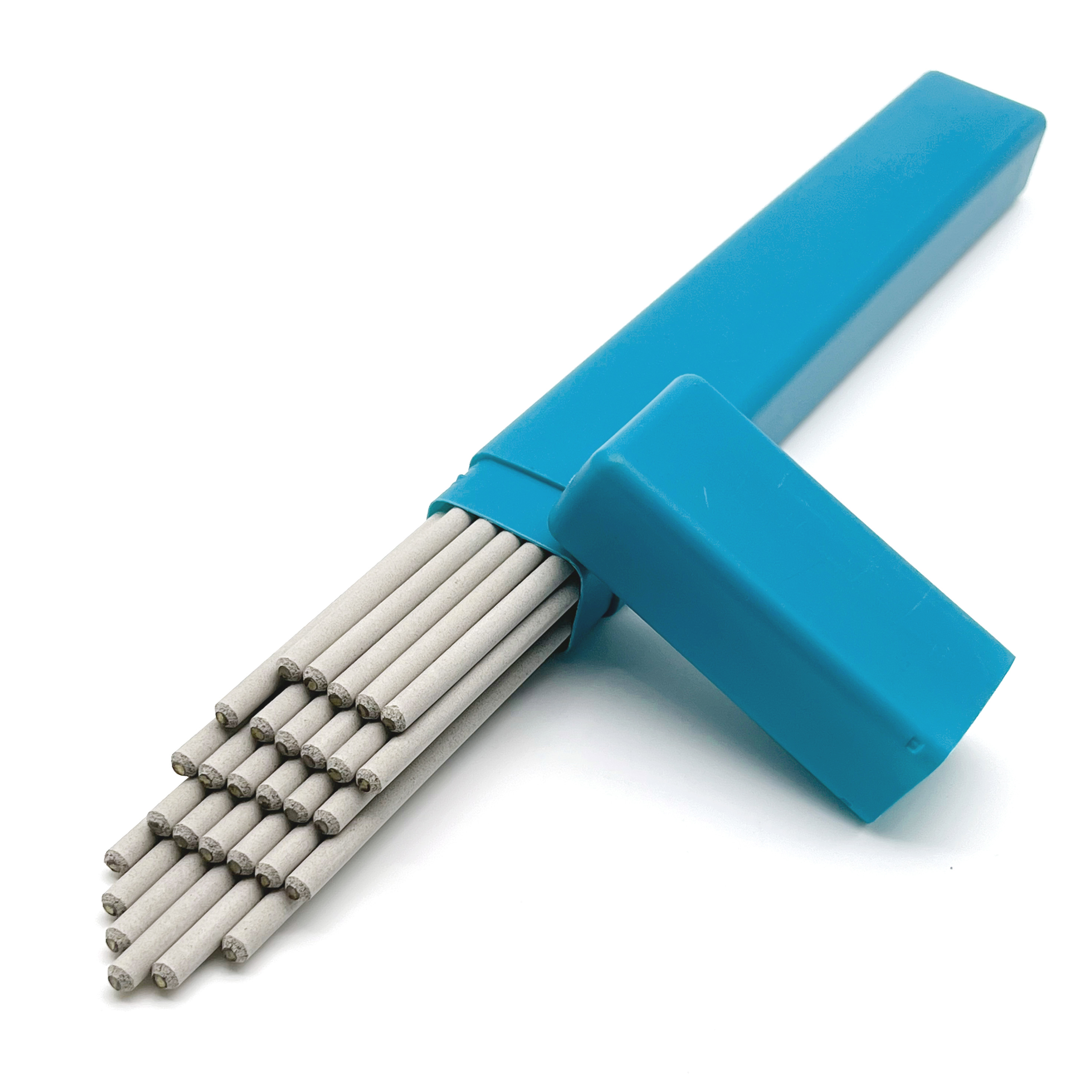

LIKOPO:

Welding ea 9% Cr-1% Mo litšepe le 9% Cr - 2% Mo litšepe tse sebelisetsoang matla a motlakase le sekepe se phahameng sa khatello.

TLHALOSO:

PA-8016-B8 ke eleketrode e tlase ea haedrojene eo tšepe ea weld e nang le 9% Cr-1% Mo.E etselitsoe tšepe ea mocheso o phahameng le litšepe bakeng sa lits'ebeletso tse chesang tsa hydrogen, haholo indastering ea petrochemical.Electrode e ka amoheloa ka lebaka la matla a eona a phahameng a ho tsitsa, ho tiea ho hotle le ho hanyetsa mocheso o moholo.

LINTLHA TSA HO SEBELISA:

1. Omisa li-electrode ho 350-400 ° C hoo e ka bang hora e le 'ngoe pele u sebelisoa' me u boloke li-electrode ho 100-150 ° C ka mor'a ho omisa ka hloko ho qoba mongobo.

2. Amohela mokhoa oa ho khutlela morao kapa otla arc holim'a poleiti e nyane ea tšepe e lokiselitsoeng morero ona ho thibela li-blowholes ho arc ho qala.

3. Boloka arc e khutšoanyane kamoo ho ka khonehang.

4. Preheat ka 100-150 ° C.Thempereichara e lokelang ho sebelisoa e fapana ho latela botenya ba poleiti le mofuta oa tšepe e lokelang ho chesetsoa.

5. Ela hloko hore u se ke ua feta mocheso o nepahetseng oa mocheso hobane mocheso o feteletseng o kenya letsoho o baka ho senyeha ha litekanyetso le ho hlahisa matla a tšepe ea weld.

IV.MOSEBETSI OA K'hemik'hale OA WELD METAL (%):

| C | Si | Mn | Cr | Mo |

| 0.06 | 0.42 | 0.68 | 9.38 | 1.05 |

V. LITABA TSA MOSEBETSI OA MOSEBETSI OA WELD METAL:

| Matla a Tensile N/mm2(Ksi) | Hlahisa Ntlha N/mm2 (Ksi) | Elongation % | PWHT |

| 705 (102) | 560 (81) | 24 | 740°C x 1 hora |

VI.MAEMO A CHESO: MAEMO TSOHLE

VII.BOLEMO LE BO KHOTHATSANG BJA RONA JOALE (AC/DC+):

| Diameter (mm) | 2.5 | 3.2 | 4.0 | 5.0 | |

| Bolelele (mm) | 350 | 350 | 400 | 400 | |

| Ampere | E bataletseng | 55-85 | 90 - 130 | 130 - 180 | 180 - 240 |

| V & OH | 50 - 80 | 80 - 115 | 110 - 170 | 150-200 |