Ho tjheseletsa Tšepe e sa KhaotsengElektrode

G207NiMo

GB/T E410NiMo -15

AWS E410NiMo -15

Tlhaloso: G207NiMo ke electrode ea tšepe e sa hloekang ea martensitic e nang le sodium e tlase ea haeterojene. Sebelisa DCEP (electrode ea hona joale e tobileng e ntle) 'me e ka kopanngoa libakeng tsohle. Lera la bokaholimo le na le thepa e ntle ea ho thibela ho qhaqhoa ha lehloa le ho se ke ha e-ba le lehlabathe. Mokhoa oa ho tjheseletsa bokaholimo o bonolo, ha ho hlokahale hore ho futhumatsoe pele ho tjheseletsa, ha ho hlokahale kalafo ea mocheso kamora ho tjheseletsa, 'me lera la bokaholimo le ka etsoa ka mochini.

Tšebeliso: E sebelisoa haholo bakeng sa ho lokisa ho tjheseletsa ha tšepe ea 0Cr13Ni4Mo, ho lokisa likarolo tsa phallo ea motlakase oa metsi ka mor'a ho senyeha ha cavitation, le ho tjheseletsa likarolo tsa sebopeho tsa thepa e tšoanang.

Sebopeho sa lik'hemik'hale sa tšepe e welded (%):

| C | Mn | Si | Cr | Ni | Mo | S | P |

| ≤0. 06 | ≤1.0 | ≤0.90 | 11.0 ~ 12.5 | 4.0 ~ 5.0 | 0.40 ~ 0.70 | ≤0.03 | ≤0.04 |

Litšobotsi tsa mechini tsa tšepe e welded:

| Ntho ea teko | Matla a tšepe Mpa | Ho lelefatsa % |

| E tiiselitsoe | ≥760 | ≥15 |

Khoeli e khothaletsoang:

| Bophara ba molamu (mm) | 3.2 | 4.0 | 5.0 |

| ho tjheseletsa hona joale (A) | 80 ~ 120 | 120 ~ 160 | 150 ~ 190 |

Tsebiso:

1. Electrode e lokela ho besoa hora e le 'ngoe mochesong o ka bang 300℃ pele ho ts'ebetso ea ho tjheseletsa;

2. Ho bohlokoa ho hlwekisa mafome, sekala sa oli, metsi le litšila likarolong tsa ho tjheseletsa pele ho tjheseletsa.

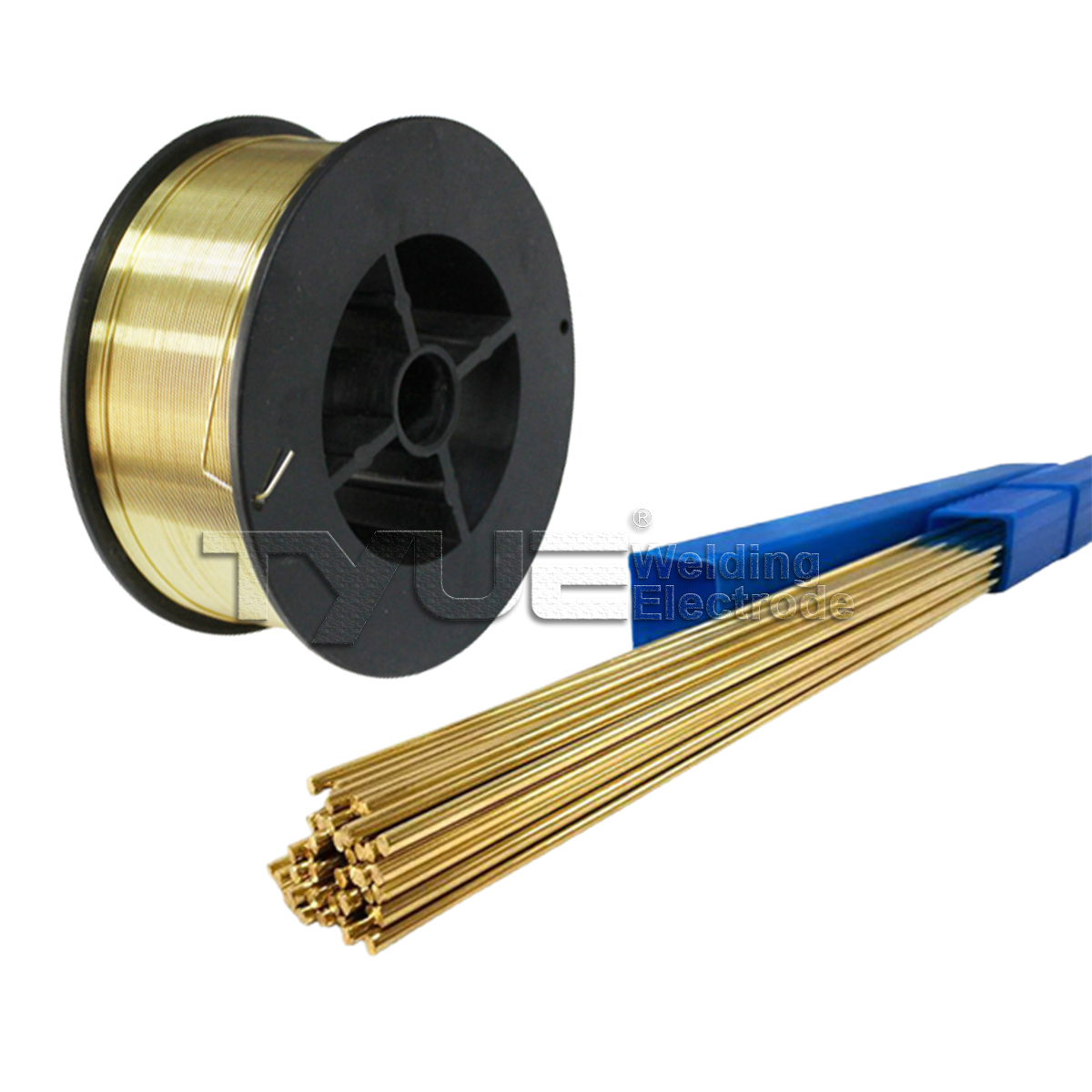

Wenzhou Tianyu Electronic Co., Ltd. e thehiloe ka selemo sa 2000. Re ntse re etsa tlhahiso eaelektrode ea ho tjheseletsas, lithupa tsa ho tjheseletsa, le lintho tse sebelisoang ho tjheseletsa ka lilemo tse fetang 20. Lihlahisoa tsa rona tse ka sehloohong li kenyelletsa tšepe e sa hloekangelektrode ea ho tjheseletsas, li-electrode tsa ho tjheseletsa tšepe ea khabone, li-electrode tsa ho tjheseletsa tse nang le alloy e tlase, li-electrode tsa ho tjheseletsa tse holim'a metsi, li-electrode tsa ho tjheseletsa tse nang le alloy ea nickel & cobalt, lithapo tsa ho tjheseletsa tse nang le alloy e bobebe le tse nang le alloy e tlase, lithapo tsa ho tjheseletsa tsa tšepe e sa hloekang, lithapo tse sirelelitsoeng ke khase, lithapo tsa ho tjheseletsa tsa aluminium, ho tjheseletsa ka har'a arc e ka tlas'a metsi. lithapo, lithapo tsa ho tjheseletsa tse nang le alloy ea nickel & cobalt, lithapo tsa ho tjheseletsa tsa koporo, lithapo tsa ho tjheseletsa tsa TIG & MIG, li-electrode tsa tungsten, li-electrode tse sehang khabone, le lisebelisoa tse ling tsa ho tjheseletsa le tse sebelisoang.