Terata ea boronse ea AWS A5.7 ERCuSn-C Phosphor

Selelekela

E kgothalletswa bakeng sa ho tjheseletsa koporo ka alloy ya Cu-Sn. E molemo ka ho fetisisa bakeng sa ho tjheseletsa koporo e kopanyang marago ka tshepe. Ho kgothalletswa ho futhumatsa pele bakeng sa dihlahiswa tse kgolo, mme ho kgothalletswa ho tjheseletsa arc ya argon e pulsed bakeng sa ho shebana le hard facing ya multilayer hodima tshepe.

| Ho leka-lekanya maemo: | Letšoao la Lipalo: | |

| GB/T9460-2008 | SCu5210 | |

| AWS A5.7:2007 | ERCuSn-C | |

| BS EN14640:2005 | Cu 5210 | |

| Sebopeho (boleng bo tloaelehileng): | % | |

| Cu ho kenyeletsoa le ag | bal. | |

| Zn | 0.20 | |

| Sn | 7.00-9.00 | |

| Fe | 0.10 | |

| P | 0.10-0.35 | |

| Al | 0.01 | |

| Pb | 0.02 | |

| Kakaretso ea tse ling | 0.50 | |

| Thepa ea 'mele ea thepa: | ||

| Botenya | Kg/m3 | 8.8 |

| Sebaka sa ho qhibiliha | ℃ | 875-1025 |

| Ho khanna ha mocheso | W/mK | 66 |

| Ho tsamaisa motlakase | Semi/mm2 | 6-8 |

| Tekanyo e sebetsang ea katoloso ea mocheso | 10^-6/K(20-300℃) | 18.5 |

| Litekanyetso tse tloaelehileng tsa tšepe ea weld: | ||

| Ho lelefatsa | % | 20 |

| Matla a tšepe | N/mm2 | 260 |

| Mosebetsi oa ho ama bareng ka mokhoa o sa reroang | J | 32 |

| Bothata ba Brinell | HB 2.5/62.5 | 80 |

| Likopo: | ||

| Motsoako oa koporo oa tin o nang le bothata bo eketsehileng ba peresente ea tin bakeng sa ho tjheseletsa ka holimo. E loketse haholo bakeng sa ho tjheseletsa thepa ea koporo, joalo ka koporo, li-bronze tsa tin, haholo-holo e sebelisetsoang ho kopanya li-alloy tsa koporo tsa zinki le litšepe. E loketse ho tjheseletsa li-bronze tse entsoeng ka cast le bakeng sa ho kopanya ka ontong. Bakeng sa ho tjheseletsa ka mekhahlelo e mengata holim'a tšepe, ho tjheseletsa ka arc e pulsed ho khothaletsoa. Bakeng sa likarolo tse kholo tsa mosebetsi ho khothaletsoa ho futhumatsa pele. | ||

| Boelana: | ||

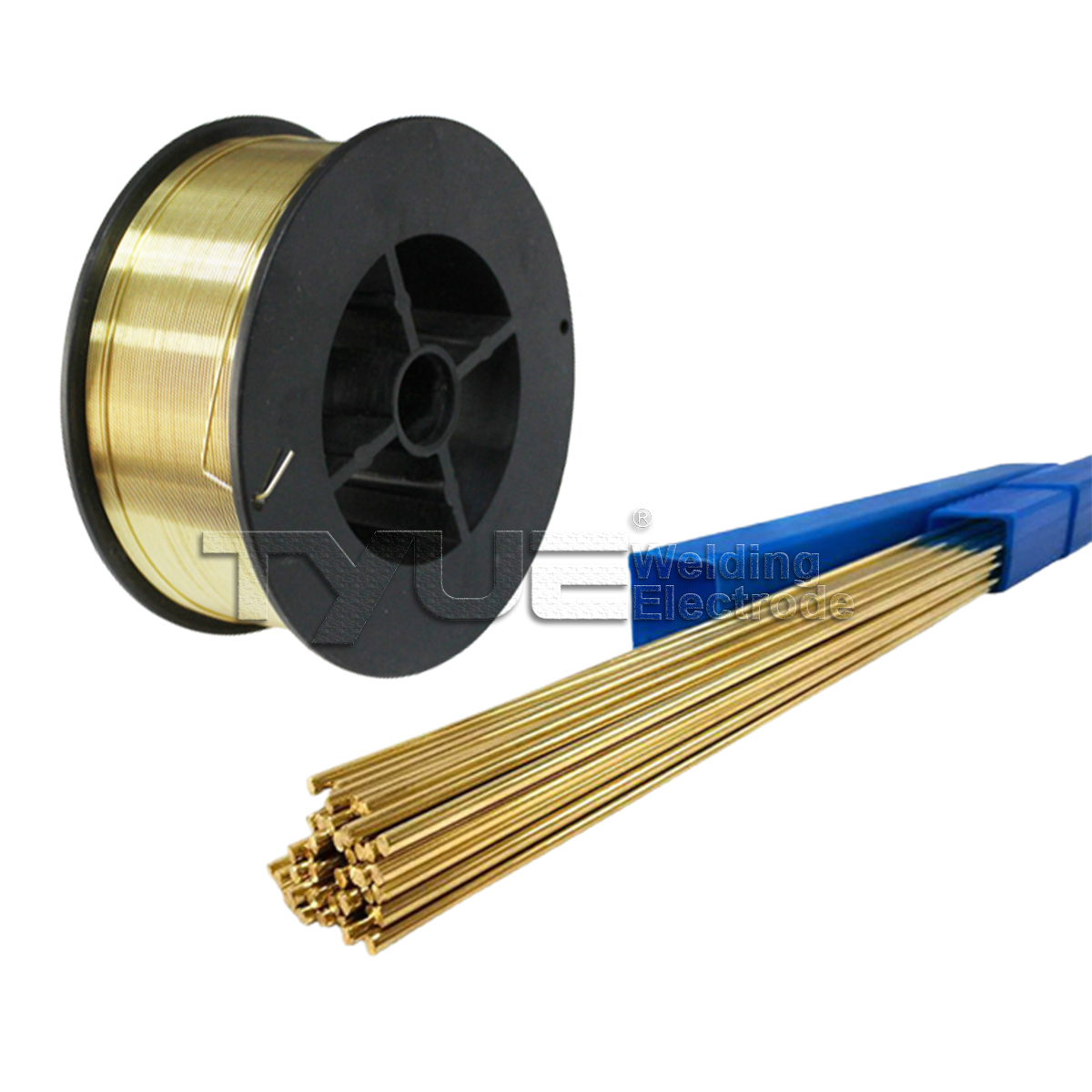

| Bophara: 0.64 – 0.80 – 1.00 – 1.20 – 1.60 – 2.40 | ||

| Li-spool: D100, D200, D300, D760, K300, KS300 | ||

| Lithupa: 1.60 – 9.6 mm x 914/1000 mm | ||

| Li-electrode lia fumaneha. | ||

| Litlolo tse ling ha ho kopuoa. | ||

Wenzhou Tianyu Electronic Co., Ltd. e thehiloe ka selemo sa 2000. Re 'nile ra kopanela tlhahisong ea li-electrode tsa ho tjheseletsa, lithupa tsa ho tjheseletsa le lisebelisoa tse sebelisoang tsa ho tjheseletsa ka lilemo tse fetang 20.

Lihlahisoa tsa rona tse ka sehloohong li kenyelletsa li-electrode tsa tšepe e sa hloekang, li-electrode tsa tšepe ea khabone, li-electrode tsa ho tjheseletsa tse nang le alloy e tlase, li-electrode tsa ho tjheseletsa tse holim'a metsi, li-electrode tsa ho tjheseletsa tse nang le alloy ea nickel & cobalt, lithapo tsa ho tjheseletsa tse nang le alloy e bobebe le e nang le alloy e tlase, lithapo tsa ho tjheseletsa tse nang le alloy e sirelelitsoeng ke khase, lithapo tsa ho tjheseletsa tsa aluminium, ho tjheseletsa ka har'a arc e ka tlas'a metsi. lithapo, lithapo tsa ho tjheseletsa tse nang le alloy ea nickel & cobalt, lithapo tsa ho tjheseletsa tsa koporo, lithapo tsa ho tjheseletsa tsa TIG & MIG, li-electrode tsa tungsten, li-electrode tse sehang khabone, le lisebelisoa tse ling tsa ho tjheseletsa le tse sebelisoang.