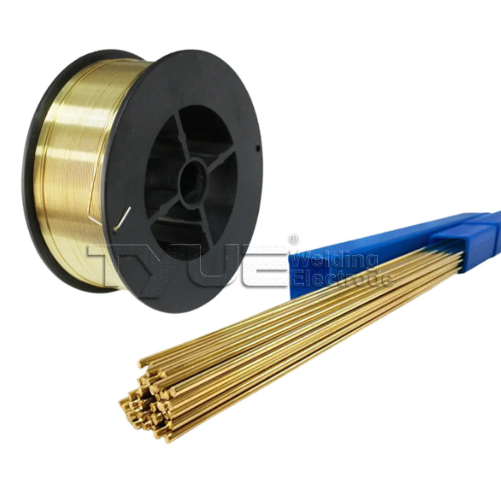

Terata ea ho tjheseletsa ea motsoako oa koporoke sesebelisoa sa ho tjheseletsa sa boleng bo holimo se etselitsoeng ho kopanya li-alloy tsa koporo le koporo-tin. Terata ea ho tjheseletsa ea alloy ea koporo e na le litšobotsi tse 'ne tsa bohlokoa: ho lumellana hantle ha thepa, bonolo ba tšebeliso, boleng bo phahameng ba ho tjheseletsa le ho hanyetsa mafome ho babatsehang. Terata ea ho tjheseletsa ea alloy ea koporo ka tlhaho e fetoha khetho e ntle bakeng sa lits'ebetso tsa indasteri le tsa DIY.

Terata ea ho tjheseletsa ea alloy ea koporo e loketse tlhahiso ea indasteri 'me e ipabola ho tjheseletseng likarolo tsa alloy ea koporo le koporo-tin mechineng, lisebelisoa le lisebelisoa. Litsamaisong tsa liphaephe le tsa HVAC, terata ea ho tjheseletsa ea alloy ea koporo ke ea bohlokoa bakeng sa ho hokahanya liphaephe le lisebelisoa tsa koporo, 'me terata ea ho tjheseletsa ea alloy ea koporo e netefatsa likhokahano tse tšepahalang litsamaisong tsa ho futhumatsa le ho pholisa. Terata ea ho tjheseletsa ea alloy ea koporo e sebelisoa lits'ebetsong tsa motlakase le tsa elektroniki bakeng sa ho tjheseletsa ka nepo lihokelo tsa motlakase, li-terminal le likarolo tse ling tse thehiloeng koporo. Indastering ea likoloi, terata ea ho tjheseletsa ea alloy ea koporo ke khetho e tšepahalang bakeng sa ho lokisa le ho etsa likarolo tsa koporo tse kang li-radiator le litsamaiso tsa motlakase. Terata ea ho tjheseletsa ea alloy ea koporo le eona ke khetho ea pele bakeng sa litsebi tsa bonono le litsebi tsa mesebetsi ea matsoho tse sebelisang alloy ea koporo le koporo mererong ea bonono le ea litšoantšo.

Terata ea ho tjheseletsa ea alloy ea koporo e na le ho lumellana ho hoholo ha thepa 'me e etselitsoe ho tjheseletsa li-alloy tsa koporo le koporo-tin ho netefatsa hore manonyeletso a matla le a tšoarellang. Terata ea ho tjheseletsa ea alloy ea koporo e lumellana le mefuta e fapaneng ea thepa e thehiloeng koporo 'me ke khetho e feto-fetohang le e tšepahalang. Terata ea ho tjheseletsa e bonolo ho e sebelisa, ea qhibiliha butle-butle, 'me ho fafatsa ho fokola, ho etsa hore ts'ebetso ea ho tjheseletsa e be bonolo ebile e laolehe habonolo. Terata ea ho tjheseletsa ea alloy ea koporo e loketse lits'ebetso tsa ho tjheseletsa tsa letsoho le tsa othomathiki ho fihlela litlhoko tse fapaneng tsa basebelisi. Boleng bo phahameng ba ho tjheseletsa bo fanoang ke terata ea ho tjheseletsa ea alloy ea koporo bo netefatsa hore tjheseletso e matla, ea tšepahala, e ntle ebile e na le thepa e ntle ea mechini, 'me e tsitsitse joalo ka tloaelo esita le libakeng tse thata tsa indasteri. Manonyeletso a tjheseletsang a terata ea ho tjheseletsa ea alloy ea koporo a na le khanyetso e ntle ea ho bola 'me a loketse haholo ho sebelisoa libakeng tse metsi kapa tse senyang. E boetse e bapala karolo ea bohlokoa lits'ebetsong moo bophelo ba ts'ebeletso le ho tšoarella li leng bohlokoa. Terata ea ho tjheseletsa ea alloy ea koporo ke sesebelisoa se theko e tlaase. Bokhoni bo phahameng le ts'epo ea terata ea ho tjheseletsa ea alloy ea koporo e ka fokotsa litšila tsa thepa le ho sebetsa bocha, ha ka nako e ts'oanang e fokotsa litšenyehelo tsa tlhokomelo ka li-weld tse tšoarellang nako e telele le tse tšoarellang.

Likarolo tsa bohlokoa tsa terata ea ho Welding ea Copper Alloy li kenyelletsa ho lumellana ha eona ho ntlafalitsoeng ha thepa, e leng se lumellang terata ea ho Welding ea Copper Alloy ho kopana ka mokhoa o se nang sekoli le li-alloy tsa koporo le koporo-tin, ho netefatsa boleng ba ho welding. terata ea ho Welding ea Copper Alloy e fana ka ts'ebetso e bonolo ho e sebelisa ka ts'ebetso e tsitsitseng ea arc le ho fafatsa ho fokolang, e fanang ka boiphihlelo bo hloekileng le bo sebetsang ba ho welding. terata ea ho Welding ea Copper Alloy e hlahisa li-weld tse sebetsang hantle tse matla, tse tšoarellang le tse ntle ka ponahalo, tse fihlelang maemo a indasteri. Sebaka sa ho welding sa.Terata ea ho Welding ea Copper Alloy e na le khanyetso e matla ea mafome, e netefatsang ts'ebetso e tšoarellang nako e telele esita le libakeng tse thata. Sehlahisoa sena sa Terata ea ho Welding ea Copper Alloy se fihlela litlhaloso tsa AWS A5.7 ERCuSn-C, se tiisang boleng le ts'epo. Ho tenyetseha ha Terata ea ho Welding ea Copper Alloy ho etsa hore e lokele mefuta e mengata ea lits'ebetso ho tloha tlhahisong ea indasteri ho ea mererong ea bonono, e leng se etsang hore Terata ea ho Welding ea Copper Alloy e be khetho e tšepahalang bakeng sa litsebi le batho ba sa rutehang.

Terata ea ho tjheseletsa ea motsoako oa koporoe lekana le sehlahisoa se kopanyang ts'ebetso e ntle haholo, ho tšoarella le ho boloka litšenyehelo li le ntle. Terata ea ho tjheseletsa ea alloy ea koporo e ka bapala karolo e ntle haholo mererong ea indasteri, litsamaisong tsa liphaephe, likarolo tsa motlakase, litokiso tsa likoloi le mesebetsi ea bonono, 'me ke sesebelisoa se sebetsang sa bohlokoa ka ho fetisisa.

Nako ea poso: Hlakubele-13-2025